The Craftsmanship Behind Gracie - Our Iconic WACO Biplane

Gracie flying over the Peace River at sunset

Introduction

Few aircraft capture the romance of aviation’s golden age quite like the WACO biplane. With its sweeping wings, open cockpit, and elegant curves, it embodies the artistry and engineering precision that defined early aviation. Our very own Gracie is more than just an airplane. She is a living tribute to history, craftsmanship, and the passion that keeps these rare flying machines in the sky.

We’d like to take you on a journey through WACO biplane history, explore the unique details that make Gracie so special, dive into the craftsmanship behind her construction and maintenance, and explain why this dedication matters for both aviation and culture today.

Gracie – A Piece of WACO Biplane History

Top: A 1934 WACO YMF-5 parked outside a hangar at Gooding Municipal Airport in Idaho, circa 1935

Bottom: Gracie, our 2000 WACO YMF-5 at Punta Gorda Airport, September 2025

Gracie’s story begins with the legacy of the WACO Aircraft Company, one of the most prominent builders of civil biplanes in the 1920s and 1930s. Originally based in Troy, Ohio, WACO produced thousands of reliable and beautiful airplanes for pilots, barnstormers, and flying clubs. Their aircraft were known for a perfect blend of performance, durability, and style, making them a favorite choice for private aviators.

Our WACO biplane—lovingly named Gracie—was designed during an era when flying was as much an adventure as it was a form of transportation. These aircraft connected communities, carried mail, and thrilled crowds at airshows.

Gracie’s airframe carries the spirit of her original era, while careful attention to detail ensures she remains airworthy for modern skies. Owning and maintaining her isn’t just about flying—it’s about keeping a vital chapter of WACO biplane history alive.

Unique Craftsmanship that Defines a WACO Biplane

Wooden Framework

Sitka Spruce is the perfect wood for airplane construction.

It is easily worked, resistant to rotting, and has no odor.

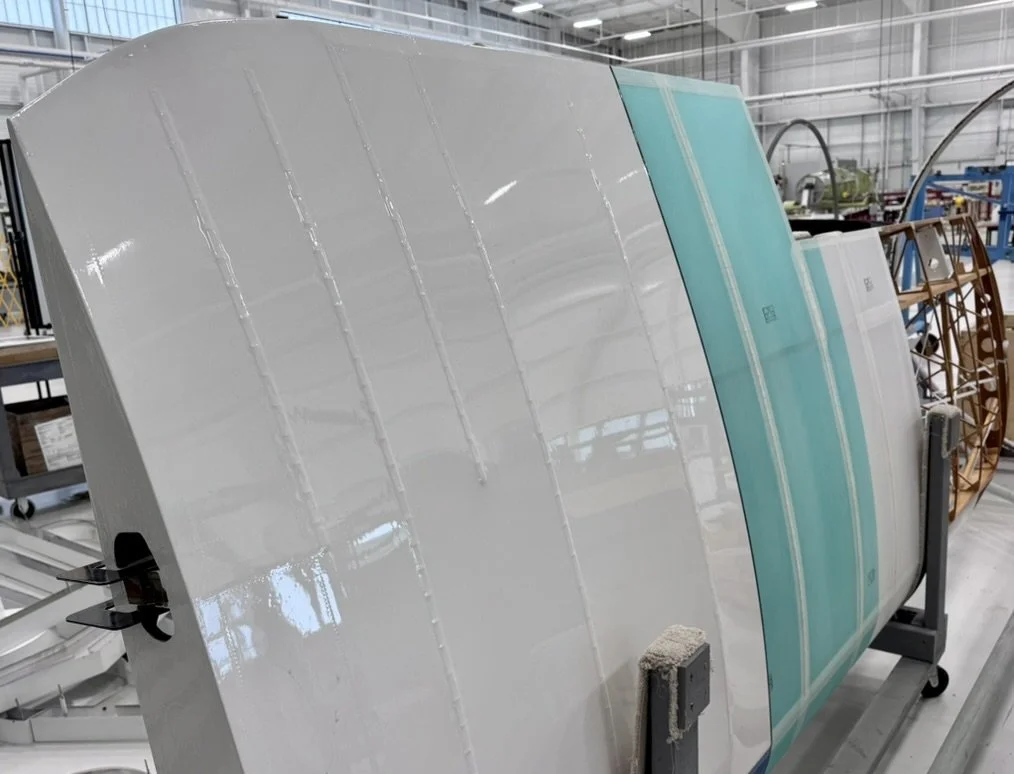

This fuselage is under construction at the WACO Aircraft Corporation’s factory located at Battle Creek Executive Airport in Battle Creek, Michigan.

We recently had a fantastic tour of their facility, which hand-builds WACOs, Great Lakes and the stunning new Junkers A50 Junior.

At the heart of Gracie is her wooden structure, crafted primarily from Sitka spruce. This wood was chosen for its incredible strength-to-weight ratio and flexibility. Shaped, glued, and reinforced by hand, the wooden framework requires many hours of exacting work. Every joint, spar, and rib has to be perfect—not just for performance, but for safety.

Fabric Covering

Another picture from our Battle Creek tour!

Every YMF-5 is lovingly built by artisans with time-honored skills and takes 6000 hours of labor!

Gracie’s wings and fuselage are manufactured using the Ceconite fabric system. Unlike traditional cotton or linen which were shrunk (tautened) by dope, Ceconite is precisely shrunk by heat, using a calibrated clothing iron. This lets the assembler control the shrinking, giving unmatched command of the covering process, producing predictably superior results every time. The shimmering finish you see on Gracie today is the result of this careful, multi-layer application and sanding, a true example of aircraft craftsmanship.

Hand-Finished Details

Have you ever noticed the logo on Gracie’s tail?

Originally the Weaver Aircraft Company of Ohio, WACO became the WACO Aircraft Company in 1928/29. When construction began again in 1986, the name ‘WACO Classic’ was adopted.

From polished fittings to custom stitching on the cockpit interior, WACO biplanes like Gracie showcase an attention to detail that borders on artistry. Many parts are hand-machined, meaning no two aircraft are completely identical.

The Open Cockpit Experience

Nothing compares to flying in an open cockpit!

Gracies’ passengers sit in the front cockpit, with panoramic views…and of course, the wind in their hair.

Flying in Gracie is a sensory experience—wind rushing past, the roar of the radial engine, and panoramic views that modern enclosed aircraft simply can’t offer. This design embodies the daring spirit of aviation’s pioneers.

Maintenance – Keeping Gracie in the Sky

In 2024, Gracie’s Jacobs R-755B engine was completely replaced. For safety reasons, the FAA mandates that the big radial is overhauled or replaced every 1400 hours.

Hidden beneath the cowling, you rarely get to see this magnificent seven-cylinder radial engine in all its glory. Ours came from Pete Jones at Air Repair in Cleveland Mississippi.

Keeping Gracie flight-ready requires constant dedication and specialized knowledge of vintage aircraft.

Meticulous Cleaning: Gracie is carefully wiped down at the end of every day, and between flights as necessary. Not only does this keep her in tip-top condition, it allows us to check every inch for damage or deterioration. Once a month she is deep cleaned from head-to-toe and a new coat of wax is applied

Regular Inspections: Every 50 hours, wooden components are checked for stress, fabric for tension, and fittings for wear. Engine oil and filter are changed, and all moving parts are thoroughly lubricated.

Engine Overhauls: Gracie’s magnificent radial engine is a mechanical masterpiece, requiring skilled mechanics who understand vintage powerplants. Every 1400 hours the engine is completely overhauled.

Traditional Skills Preserved: Maintenance involves techniques like fabric covering, wood spar repair, and control surface rigging—crafts nearly lost in modern aviation.

Why the Craftsmanship Matters

Preserving History

Every screw, rib stitch and spar of Gracie tells a story. She represents a time when aviation was daring, adventurous, and deeply personal.

Celebrating Human Skill

In an era of ever-increasing automation, Gracie reminds us of what skilled hands can achieve. Her very existence highlights the timeless value of aircraft craftsmanship.

An artisan at the WACO Aircraft Corporation shaves a wing surface to perfection

Inspiring Future Aviators

Young visitors who see her at airshows are often captivated. For many, *Gracie* sparks an interest in aviation, mechanics, or history.

Curtiss the Hawk is the airport mascot at our home field, Punta Gorda Airport.

Here we see Curtiss demonstrating to a group of local school kids how to get into Gracie’s front cockpit.

Connecting Generations

Fathers and sons, grandparents and grandkids, adult kids with aging parents…they all love Gracie!

Flying in or simply watching Gracie connects us with aviation’s heritage, uniting people across towns, countries, and generations.

Gracie is more than just an airplane—she is a living piece of WACO biplane history and a symbol of the artistry that defined aviation’s golden era. Her wooden framework, fabric wings, and roaring radial engine are the result of skilled human hands and timeless design.

Flying in Gracie helps to ensure that traditional aircraft craftsmanship continues to inspire, educate, and connect future generations. Each flight is a reminder that aviation is not only about reaching a destination—it’s about honoring the craft, dedication, and spirit that make the journey unforgettable.

Inspired by Gracie’s story? Book your own open cockpit adventure today and make history part of your journey.